Predator MDC™ with OPC

Why use Predator MDC with OPC?

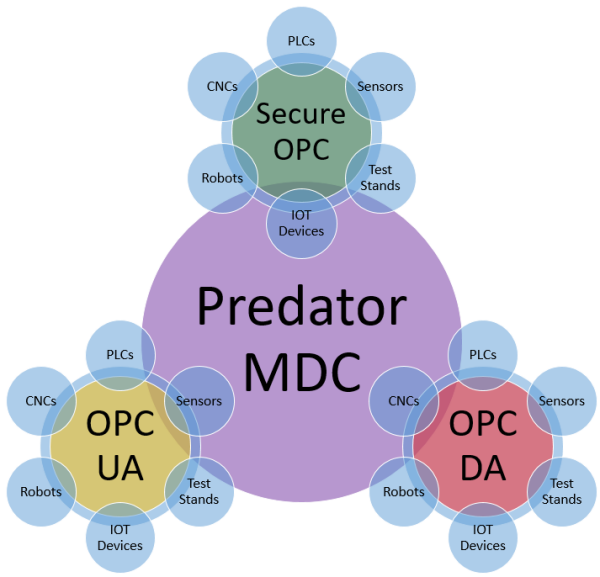

Leverage the power of Predator MDC with OPC DA and OPC UA protocols to simplify and track PLCs, CNC machines, robots, IOT devices, sensors, test stands and other industrial devices and their productivity via Ethernet based data collection.

- Track cycle time, setup time, teardown time, downtimes, idle time, good parts, scrap parts, etc.

- Actual metrics per job, part, operation, traveler, customer, department, shift, user, cell and more

- Works with a wide range of OPC enabled PLCs, CNC machines, robots, IOT devices, sensors and test stands

- Ethernet based interface

- Software based no special data collection hardware required

OPC DA and OPC UA Support

OPC DA and OPC UA client support is included with the purchase of Predator MDC.

Predator Secure OPC Support

Predator Secure OPC eliminates the requirement to use DCOM for remote Ethernet access to OPC DA servers. Predator Secure OPC provides this "tunnel" with automatic authentication, encryption and compression. Predator Secure OPC supports OPC DA servers running on Windows 95 or newer, and eliminates the need for them to be members of the corporate domain. Finally, Predator Secure OPC provides server based management and tag configuration. Updates to Predator Secure OPC can even be pushed from your server, minimizing the need to physically touch each PLC, CNC machine, robot or industrial equipment. Predator Secure OPC is included free with the purchase of Predator MDC.

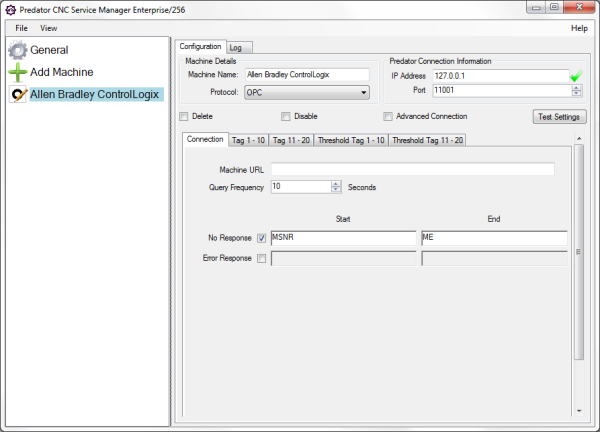

Predator CNC Service

Leverage the power of OPC with Predator CNC Service to provide intelligent software based machine monitoring via an Ethernet interface. Predator CNC Service supports machine operation modes, cycle counters and more for all makes and models of OPC enabled PLCs, CNC machines, robots, IOT devices, sensors, test stands and other industrial devices.

The following software based data collection details per device are supported:

- Up to 50 Custom Tags

- Up to 50 Custom Threshold based Tags

- Optionally scale values for automatic unit conversions

- and more...

Predator MDC supports custom data collection should additional details be required.

NOTE: Predator MDC supports OPC DA, Secure OPC and OPC UA via Ethernet. An OPC DA Server or OPC UA Server may have to be purchased from the PLC manufacturer, robot builder, machine tool builder or machine tool distributor. Whenever possible, existing OPC DA and OPC UA servers will be used.

What does the acronym OPC stand for?

OPC is short for Open Platform Communications. Originally, it stood for OLE for Process Control. OLE is short for Object Linking and Embedding.

What does the acronym OPC DA stand for?

OPC DA is short for Open Platform Communications Data Access.

What does the acronym OPC UA stand for?

OPC UA is short for Open Platform Communications Unified Architecture.

What are the differences between OPC DA and OPC UA?

OPC DA was originally introduced in 1996 and it requires Microsoft's COM and DCOM technology. OPC UA was introduced 10 years later in 2006 and it eliminates the requirement for Microsoft's COM and DCOM. In addition, OPC UA adds the ability to provide security to the data collection process. OPC UA is significantly more complicated that OPC DA.

Do all OPC server's include OPC DA and OPC UA data collection protocols?

No, it is not required that all OPC servers support both protocols.

How does the OPC UA protocol work?

There are actually two variants of OPC UA. The binary variant provides the best performance with the least amount of overhead. The second variant utilizes SOAP, XML and HTTP.

What security elements are included within OPC UA?

OPC UA includes authentication, authorization, encryption and signatures for data integrity.

OPC Membership

Predator Software has been an OPC member of the OPC Foundation for many years to ensure that the latest OPC technologies are included with Predator MDC. Compatibility with thousands of products from a wide range of vendors is possible with OPC UA and OPC DA technology.