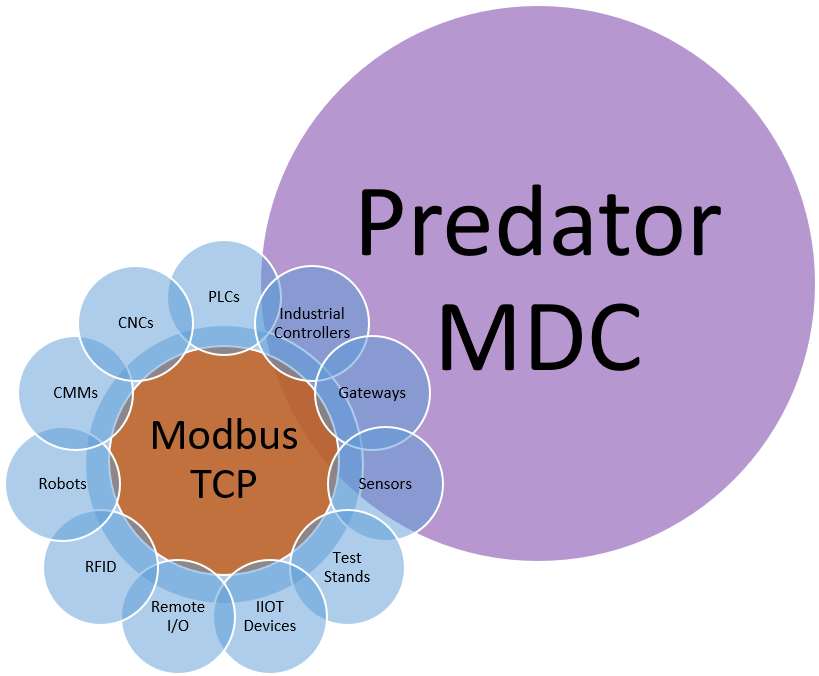

Predator MDC™ with Modbus

Why use Predator MDC with Modbus?

Leverage the power of Predator MDC with the Modbus TCP protocol to simplify and track PLCs, industrial controllers, gateways, CMMs, CNC machines, robots, RFID, IIOT devices, remote I/O, sensors, test stands and other industrial equipment for their productivity via Ethernet based data collection.

- Track cycle time, setup time, teardown time, downtimes, idle time, good parts, scrap parts, etc.

- Actual metrics per job, part, operation, traveler, customer, department, shift, user, cell and more

- Works with a wide range of Modbus enabled idustrial equipment

- Ethernet based interface

- Software based no special data collection hardware required

Modbus TCP Support

Modbus TCP support is included with the purchase of Predator MDC.

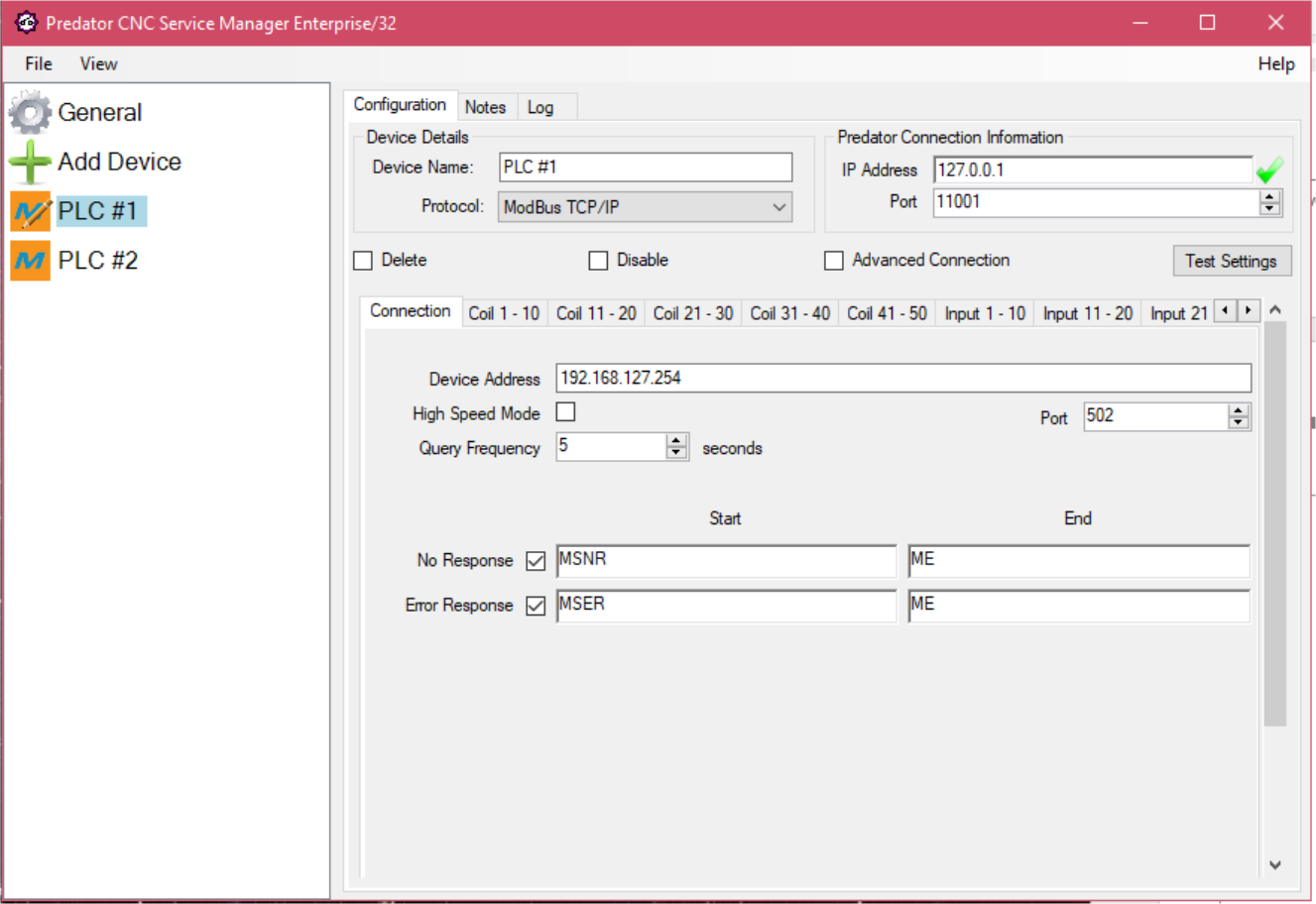

Predator CNC Service

Leverage the power of Modbus TCP with Predator CNC Service to provide intelligent software based machine monitoring via an Ethernet interface. Predator CNC Service supports machine operation modes, cycle counters and more for all makes and models of Modbus enabled PLCs, industrial controllers, gateways, CMMs, CNC machines, robots, RFID, IIOT devices, remote I/O, sensors, test stands and other industrial equipment.

The following software based data collection details per device are supported:

- Up to 50 Coils for Digital I/O

- Up to 50 Inputs for Digital I/O

- Up to 50 Input Registers

- Up to 50 Holding Registers

- and more...

Predator MDC supports custom data collection should additional details be required.

NOTE: Predator MDC supports Modbus TCP via Ethernet. Modbus support or configuration may have to be purchased from the PLC manufacturer, robot builder, machine tool builder or machine tool distributor. Whenever possible, existing Modbus TCP options will be used.

What is a Modbus Coil?

A Modbus coil is a Digital Input or Output that is represented as a single bit within the protocol.

What is a Modbus Discrete Input?

A Modbus Discrete Input is a Digital Input that is represented as a single bit within the protocol.

What is a Modbus Input Register?

A Modbus Input Register is a read only numeric value that is represented as 16 bits within the protocol.

What is a Modbus Holding Register?

A Modbus Holding Register is a read or write numeric value that is represented as 16 bits within the protocol.

How many variations of Modbus are there?

Over the years, a number of Modbus variants have been developed. Refer to the following:

- Modbus RTU

- Modbus ASCII

- Modbus over TCP/IP

- Modbus over UDP

- Modbus Plus

- Pemex Modbus

- Enron Modbus

- JBUS

The above list of variants are all different than Modbus TCP and are not supported by Predator Software. Should any of the above Modbus variants be required, a gateway can be implemented.