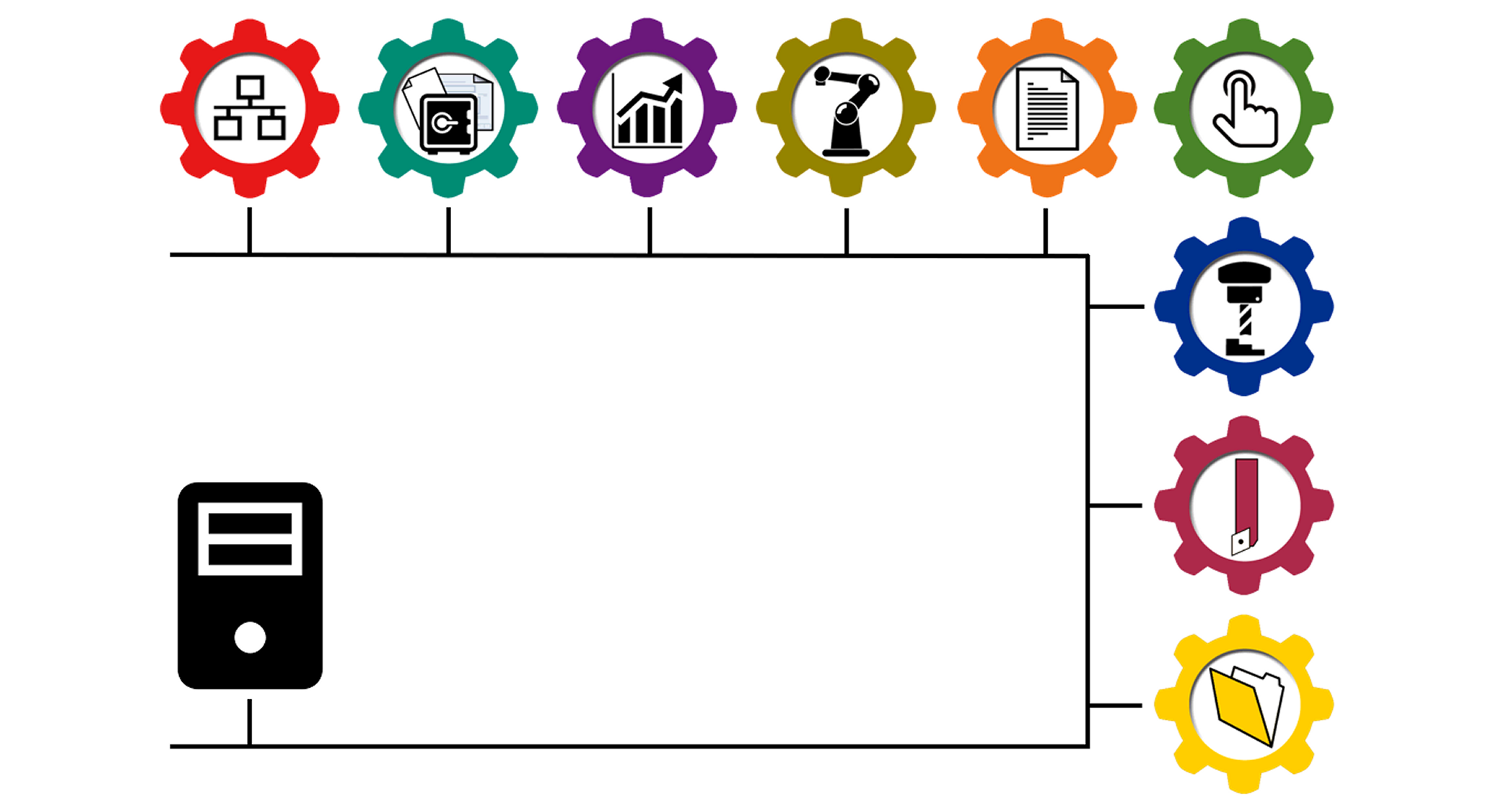

Automate your shop floor with Predator Software's Digital Factory applications and manufacture smarter

- Network CNCs, PLCs & Robots

- Wired & Wireless

- Ethernet, RS232 & Parallel

Predator PDM™

Predator PDM™

- Production Data Management

- Paperless Manufacturing

- Revision Control & Workflow

- Automatic Data Collection

- Machine Monitoring & OEE

- Dashboards, Charts & Reports

- Flexible Manufacturing System

- Lights Out Production

- Run Schedules of Small-Large Lots

Predator CNC Editor

Predator CNC Editor

- Compare & Edit G Code

- Basic DNC

- 3D Backplotting & Animation

Predator Virtual CNC

Predator Virtual CNC

- Machine Simulation & Verification

- 2-5 Axis Mills, Lathes, EDMs & 3D Printers

- Actual CNC Code

- Tool, Gage & Fixture Management

- Bar Code, QR & RFID Support

- Check In & Check Out

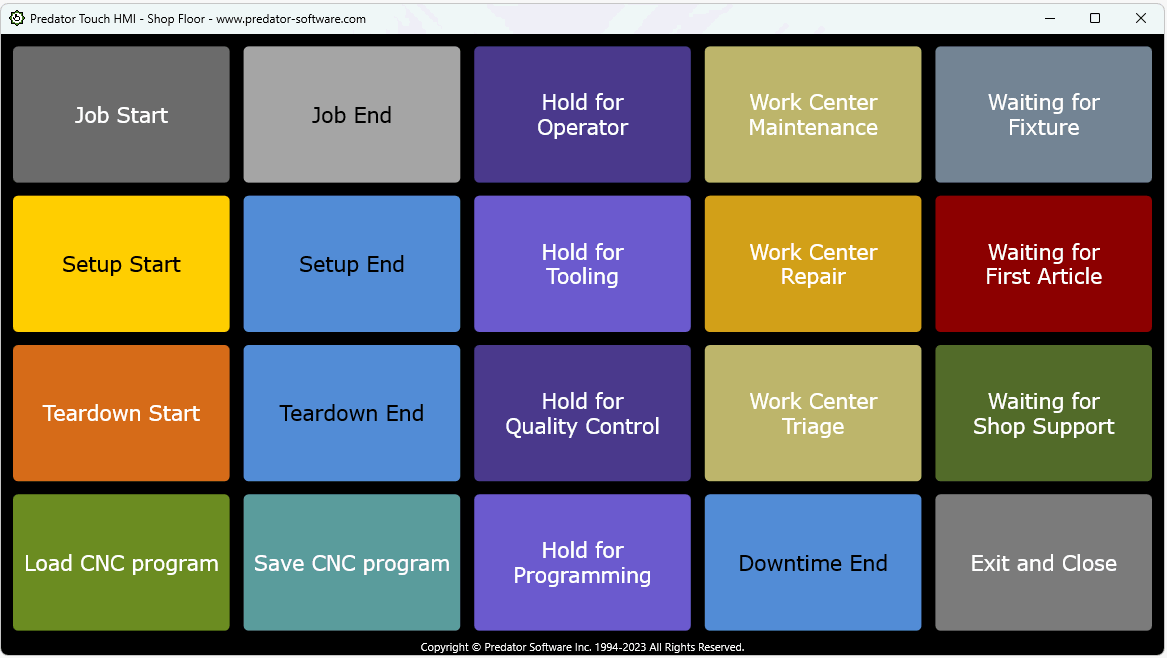

Predator Touch HMI

Predator Touch HMI

- Create Shop Floor Applications

- Touch Friendly User Interfaces

- Code Free Designer

Predator Adaptive CNC™

Predator Adaptive CNC™

- Sensor based CNC Machining

- Adaptive Fixturing

- Real-time Scheduling

Predator Adaptive CNC is designed to run CNC production schedules and reduce scrap with real-time sensor overrides.

Learn more Predator Oven Control™

Predator Oven Control™

- Control Ovens and Test Chambers

- Soaking and Ramping Recipes

- Box and Cart Management

Predator Oven Control supports up to 8 ovens/test chambers per PC w/unlimited boxes, carts, soaking & ramping recipes.

Learn more Predator Post Processor™

Predator Post Processor™

- CNC Post Processing

- 2-5 Axis Mills, Lathes & 3D Printers

- Supports APTCL, INC and NCI input

Predator Post Processor supports 2-5 axis CNC machines and 3D printers. Posts are easy to configure and customize.

Coming Soon! Multi-DNC

Multi-DNC

- Network CNCs via RS232

- Wired & Wireless

- Shop floor PC solution

Multi-DNC software provides an easy to use job shop oriented industrial network for serial based CNCs from shop floor PCs.

Learn more Predator Travelers™

Predator Travelers™

- Electronic Work Instructions

- Paperless Manufacturing

- Revision Control & Workflow

Predator FLM™

Predator FLM™

- Floating Network Licensing

- Concurrent Licensing not per User

- Windows Service

Predator Secure applications

Predator Secure applications

- Predator Secure DNC™

- Predator Secure PLC™

- Predator Secure MDC™ and more

Predator Utilities™

Predator Utilities™

- Predator Import Service™

- Predator MDC Export Service™

- Predator File Parser™ and more