Predator DNC™ Software

What is Predator DNC?

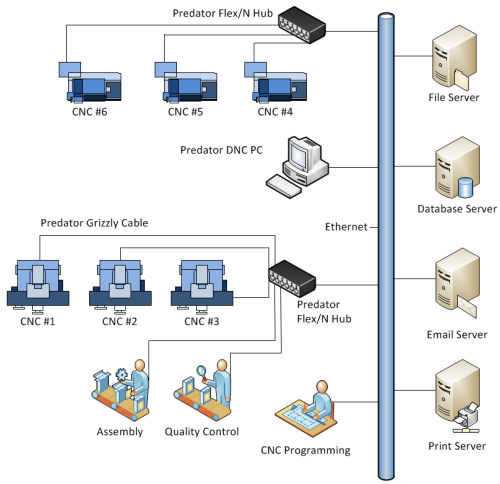

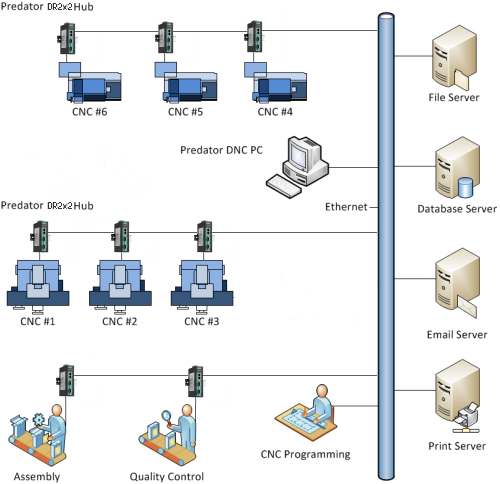

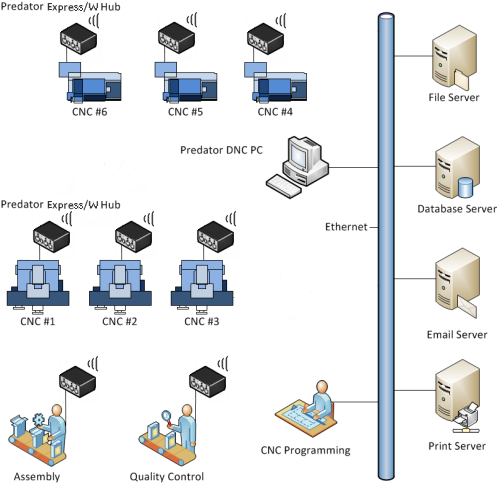

Predator DNC software provides an industrial networking solution for all of your CNC machines, robots, CMMs, PLCs, laser markers, dot peen markers, tool presetters and test stands. Predator DNC transfers your CNC programs, CNC variables, offsets, parameters, PLC registers and other production data to and from your manufacturing equipment. It supports 50+ industrial communication protocols for dripfeeding, downloading, and uploading via parallel, RS-232, RS-422, Ethernet and wireless Ethernet. Predator DNC can run as a Windows Service or as a Windows application. Choose from three editions:

- Predator DNC Express™

- Predator DNC™

- Predator DNC Enterprise™

Why use Predator DNC ?

- One industrial network for all your CNC machines, robots, CMMs, PLCs, 3D printers and more

- Send, receive and dripfeed CNC programs, offsets, variables and registers

- Supports ISO, conversational and binary file formats

- Mid-program restart after tool breaks

- Supports wireless, ethernet, RS-232 and parallel I/O

- Improve CNC program and CNC variable management

- Improve CNC offset and CNC parameter management

- Eliminate walking back and forth; works from your CNC

- Supports RFID chips, bar codes or QR codes for Remote Request™

- Supports BTRs from multiple vendors for older NC style machines

- Includes a Windows Service for headless operation

- Includes support for Windows Server OSes and client OSes

- Includes support for physical PCs, VMware™, Hyper-V™ and Citrix™

- Includes Predator Secure DNC™ and Predator Secure PLC™

- Includes Predator CNC Editor™ for CNC intelligent editing, 3D backplotting and animation

- Add Predator Touch HMI™ for custom operator friendly screens

- Add Predator PDM™ for secure revision control to meet or exceed regulatory requirements for the DOD, FDA or FAA

- Upgrade to Predator MDC™ for real-time machine monitoring and data collection

- Upgrade to Predator RCM™ for real-time machine tending and automation

- Made in the USA - Learn more

Improve Shop Floor Processes

Stop using USB drives, diskettes, PCMCIA cards, switch boxes, paper tape or a proprietary hardware contraption to communicate with your CNC machines, robots, CMMs, PLCs, 3D printers, laser markers, dot peen markers, tool presetters and test stands. Predator DNC provides a true network solution ensuring the latest files are pulled from your file server or Predator PDM vaults and, when changes occur, the edits are stored back on your file server. The entire manufacturing process will become more reliable and the team will become more productive while simultanously reducing scrap and avoiding product mix problems.

Network up to 4096 machines per PC, server or VM

Predator DNC software supports up to 4096 CNC machines, robots, CMMs, PLCs, 3D printers, laser markers, dot peen markers, tool presetters and test stands per PC, server or virtual machine. Simultaneously send, receive, dripfeed, download or upload CNC programs, offsets, parameters, variables and registers. Organize your manufacturing equipment by grouping them per building or cell. Network your Predator PCs to support an unlimited number of industrial manufacturing equipment.

NOTE: Multiple machines per PC may requires compatible hardware such as Predator Express, Flex/N, Flex/W or DR 2x2 series.

ERP and MES Integration

Improve shop floor workflow by integrating Predator DNC with your ERP and MES systems. Drive the manufacturing process from ERP or MES routers or schedules. Predator DNC supports paper or paperless integration with a wide range of ERP and MES systems.

Bar Code and QR Code Operation

Reduce mistakes and avoid product mixups by mounting a bar code reader or QR code reader at each CNC machine, robot, CMM, PLC, 3D printer, laser marker, dot peen marker, tool presetter and test stand. Scan one or more bar codes and have the correct programs automatically downloaded. Support for multiple head machines guarantee that the correct programs are transferred into each head.

RFID Operation

Reduce mistakes and avoid product mixups by mounting a RFID reader at each CNC machine, robot, CMM, PLC, 3D printer, laser marker, dot peen marker, tool presetter and test stand. Scan a RFID chip mounted on the fixture or part and have the correct CNC programs and CNC variables automatically downloaded. Support for multiple head machines guarantee that the correct programs are transferred into each head.

Supports Lot Numbers and Trace Codes

High volume manufacturing workflows commonly utilize lot numbers and trace codes to reduce mistakes and avoid product mixups. Unfortunately, there are no standards for lot numbers and trace codes, so Predator Software developed a flexible library to support the unique requirements of each manufacturer.

Advanced Automation Operation

Predator DNC supports advanced automation with one or more Predator DNC functions automatically triggered via digital I/O, analog I/O, CNC variables or PLC registers. Refer to the following automation examples:

- A proximity sensor toggles a digital I/O and Predator DNC will automatically send a specific set of CNC programs and/or CNC variables to the CNC machine.

- A PLC register is used to indicate the next part number to manufacture. When the PLC register changes, Predator DNC will automatically send the matching CNC programs and CNC variables to the CNC machine.

- Combine Predator DNC with Predator EditLock hardware to lock and unlock the CNC memory. This works with any CNC machine that has an edit key.

- Enhance Predator DNC with Predator Touch HMI to build one or more shop floor HMIs to trigger any Predator DNC function.

DNC Explorer™

Predator DNC software keeps things simple with its Microsoft Office® and Windows® Explorer compatible user interface. DNC Explorer includes standard features for drag and drop, shortcut menus, cut, copy & paste, object based menus, toolbars, tool tips, and online help. The entire user interface allows you to completely customize your machine layout and operation.

Remote Request™

Eliminate walking back and forth between your CNC and your PC with Remote Request. Remote Request allows the operators on the shop floor to dripfeed, download and upload CNC programs directly from their CNC controls. Predator DNC software supports a number of remote features including Remote Autoname™ for simplified uploading of NC code remotely from the floor, Remote Messaging for visibility back to the DNC server PC when errors occur, and an unlimited number of Remote Commands per CNC.

100% Network Compatible

Predator DNC software works as a gateway between your industrial manufacturing equipment and your Windows, Linux, Solaris, Mac, VMS or Unix network server. Predator DNC extends the industrial networking flexibility of Ethernet and Windows® to your CNC machines, robots, CMMs, PLCs, 3D printers, laser markers, dot peen markers, tool presetters and test stands. Support for wired and wireless Ethernet, hidden network shares, folder shortcuts, file shortcuts, zip files and active directory are included.

Server Safe™

Predator DNC software includes a Server Safe™ option for error free DNC program transfers even if the network server should crash or fail during DNC communications. This is one of many reliability features engineered into Predator DNC.

DNC in the Background

Stuck with an old DNC program that won't multi-task? Predator DNC can support up to 4096 CNC machines, robots, CMMs, PLCs, 3D printers, laser markers, dot peen markers, tool presetters and test stands simultaneously. Background operation even includes an option for running Predator DNC as a Windows Service. Predator DNC's multi-threaded design leverages hyper-threading and multi-core CPUs to balance the number of CNCs, PLCs and robots.

DNC Objects™ - Industry Leading Flexibility

Almost 120 DNC Objects are included with the Predator DNC program. These can be combined to automate a number of shop floor processes. Options include email, HTML, CSV, printing, VB scripts or tracking in Microsoft Excel, Microsoft Access, Microsoft SQL Server or Oracle.

50+ Industrial Networking Protocols

Often Predator DNC Objects can be combined and used in series for custom communication protocols or shop floor automation. Refer to the following standard 50+ industrial protocols:

| Protocol | Interface | Application |

|---|---|---|

| ASCII - Simple | Serial, Ethernet & Parallel | CNC, PLC, Robot, CMM, 3D Printer & Other |

| ASCII - Custom | Serial, Ethernet & Parallel | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Allen Bradley SLC | Ethernet | PLC |

| Binary - Simple | Serial, Ethernet & Parallel | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Binary - Custom | Serial, Ethernet & Parallel | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Bostomatic | Serial | CNC |

| Brother Dialog | Serial | CNC |

| Bridegport Easylink | Serial | CNC |

| BTR | Parallel | Other |

| BWO DNC | Serial | CNC |

| Camate | Serial | CNC |

| Cognex Dataman | Ethernet | Other |

| Danobat | Ethernet | CNC |

| DMG Mori Seiki MAPPS | Ethernet | CNC |

| DMG Mori Seiki Celos | Ethernet | CNC |

| EIA358C | Serial | CNC & Other |

| Ethernet | Other | |

| Excellon | Serial | CNC |

| Fadal Checksum | Serial | CNC |

| Fagor 8020 | Serial | CNC |

| Fagor 8050 | Serial | CNC |

| Fanuc A | Serial | CNC |

| Fanuc Expand A | Serial | CNC |

| Fanuc Cassette | Serial | CNC |

| Fanuc FOCAS | Ethernet | CNC |

| Fanuc FOCAS Data | Ethernet | CNC |

| FTP Client | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| FTP Server | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| GE IPP | Serial | CNC |

| Haas 143 | Serial | CNC |

| Haas Data | Serial | CNC |

| Heidenhain | Serial | CNC |

| Highland BTR | Serial | CNC |

| Kauffman | Serial | CNC |

| Kermit | Serial | CNC, PLC & Other |

| Linatrol | Serial | CNC |

| LSV2 | Serial | CNC |

| Mazak Mazatrol | Serial | CNC |

| Motoman Yaskawa | Serial | Robot |

| Okuma A | Serial | CNC |

| Okuma B | Serial | CNC |

| OPC DA | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Predator CycleLock | Serial | PLC |

| Predator EditLock | Serial | PLC |

| Predator HHT | Serial | Other |

| Predator Secure DNC | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Predator Secure PLC | Ethernet | PLC |

| RS244B | Serial | CNC & Other |

| SMB | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Starlink | Serial | CNC & Other |

| TCPIP Client | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| TCPIP Server | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| Windows Printer | Ethernet | Other |

| Windows Folder | Ethernet | CNC, PLC, Robot, CMM, 3D Printer & Other |

| XModem | Serial | CNC, PLC & Other |

Predator Secure DNC™

Predator Secure DNC provides Ethernet connectivity to Windows based CNC machines, robots, CMMs, PLCs, 3D printers, laser markers, dot peen markers, tool presetters and test stands while removing them from the corporate domain while leveraging the power of Ethernet. Predator Secure DNC supports Windows 95 or newer and is included with Predator DNC.

Predator Secure DNC eliminates USB drives, administrator user access, SMB, CIFS, Windows shares, anti-malware, password changes, group policy and domain requirements.

Predator Secure PLC™

Predator Secure PLC provides Ethernet connectivity via OPC DA to PLC based machines to download and upload recipes or specific registers. Predator Secure PLC removes the industrial manufacturing equipment from the corporate domain while leveraging the power of Ethernet. Predator Secure PLC supports Windows 95 or newer and is included with Predator DNC.

Includes Windows Server™, Hyper-V, VMware and Citrix support

Predator DNC supports a wide range of platform support including Windows Server 2019 through 2008. In addition, support for Microsoft's Hyper-V, VMware and Citrix is also included. Predator DNC and Predator DNC Enterprise software includes headless operation via a true Windows Service. A wide range of optional DNC clients are supported.

Includes the Predator CNC Editor™

Every Predator DNC software license includes an integrated Predator CNC Editor for intelligent CNC editing, side-by-side file compare and 3D backplotting.

Predator DNC Enterprise - Part Numbers

| Part # | Description |

|---|---|

| 20201001 | Predator DNC Enterprise/1 |

| 20201002 | Predator DNC Enterprise/2 |

| 20201004 | Predator DNC Enterprise/4 |

| 20201008 | Predator DNC Enterprise/8 |

| 20201012 | Predator DNC Enterprise/12 |

| 20201016 | Predator DNC Enterprise/16 |

| 20201024 | Predator DNC Enterprise/24 |

| 20201032 | Predator DNC Enterprise/32 |

| 20201### | Increments of 8 up to maximum license of /4096 |

Predator DNC - Part Numbers

| Part # | Description |

|---|---|

| 20202001 | Predator DNC/1 |

| 20202002 | Predator DNC/2 |

| 20202004 | Predator DNC/4 |

| 20202008 | Predator DNC/8 |

| 20202012 | Predator DNC/12 |

| 20202016 | Predator DNC/16 |

| 20202024 | Predator DNC/24 |

| 20202032 | Predator DNC/32 |

| 20202### | Increments of 8 up to maximum license of /4096 |

Predator DNC - Popular Options

| Part # | Description |

|---|---|

| 20209000 | Predator Java Scripting |

| 20209010 | Predator Secure HID |

| 20209020 | Predator Touch HMI |

| 20209030 | Predator VB Scripting |

| 20209040 | Predator C++ SDK |

| 20209080 | Predator DNC Connect |

| 20209090 | Predator PRemote |

| 29900000 | Predator Floating License Manager - Learn more > |

Predator DNC Express - Part Numbers

| Part # | Description |

|---|---|

| 20203004 | Predator DNC Express/4 |

| 20203008 | Predator DNC Express/8 |

| 20203016 | Predator DNC Express/16 |