Predator RCM™ Software

What is Predator RCM ?

Predator RCM software is a flexible robotic cell controller and scheduler designed to automate a cell of CNC Machines, robots, CMMs, gage inspections, part markers, part cleaners and other manufacturing equipment. Predator RCM provides lights out operation and production with flexible manufacturing and complete automation. Predator RCM schedules the robot to load and unload every CNC machine, CMM, part markers, part cleaners, work centers, etc. within the cell. Hands free operation from raw material to finished parts. Predator RCM supports a wide range of pallets, tooling, RFID tags, load stations, unload stations, part washing and more. Choose from two editions:

- Predator RCM Express™

- Predator RCM™

Why use Predator RCM?

- Robotic machine tending - Load and unload CNC machines via a robot

- Automated manufacturing with small, medium and large lot sizes

- Lights Out Manufacturing

- Manage CNC programs without interrupting the CNCs within the cell

- Multiple parts/jobs per pallet

- Standard Load and Unload rack stations

- Optional Rotary Carousel style Load and Unload stations

- Manage job priorities and holds without interrupting cell production

- View cell status remotely

- Automatic Email notifications of manufacturing problems

- Automatic recovery from a problem job or CNC

- Flexible material handling

- Eliminate hundreds of PLC programming hours

- Optional part marker (laser etch, pin stamp & engrave) support

- Optional part washer and part basket support

- Optional CMM and Probe inspection with automatic offset adjustments

- Optional RFID, Tool and EDM options

- Optional Double Gripper support

- Online Help

- Made in the USA - Learn more

CNC Machine Tending Software

Maximize the productivity of your CNC machines while reducing the number of operators/labor required. With proper fixtures and robotic grippers, Predator RCM is capable of robotic machine tending (machine loading and unloading) any type of machine. Common machine types include CNC machines, CMMs, laser markers, part washers and other manufacturing and inspection processes. There are 8760 hours per year. Achieving the maximum number of production hours per machine requires automation. Predator RCM fast tracks the design and assembly of lights out capable manufacturing cells with off the shelf software, hardware, support and services.

Job Scheduling

Predator RCM's Job Manager is the scheduling center of the system. Work can be added, removed, or put on hold according to the day-to-day changes in machining priorities. Predator RCM can also allow the scheduling of work in multiple machining cells from one central console.

Presetter

Predator RCM's Presetter manages the tooling inventory in the shop and allows the operator to prepare the work, download CNC Programs from the corporate network and assemble the job to be submitted for automated machining. Each job includes a pallet and/or fixture, a workpiece, and the CNC programs required to machine the part. An individual pallet can have one or more jobs attached to it allowing for automated machining of several operations on a single workpiece.

Flexible Material Handling

In many cases, material handling can be complicated. Over the years multiple material handling modules have been developed to support machine tending a wide range of parts, pallets and tools. Predator RCM includes support for single, double and even triple grippers. Grippers and fixtures can be swapped at the beginning of a lot. Additional setup and part changeover details can also be automated.

Eliminate PLC and HMI Programming

Traditional machine tending and cell control is often done with a PLC, a HMI and hundreds of PLC programming hours. Predator RCM eliminates this and reduces the need for a PLC with smaller and simpler cells or reduces the PLC requirements to a safety PLC. Predator RCM is provides a consistent PC based HMI across multiple cells with Ethernet connectivity to the cell's machine equipment. Naitive machine APIs are used to maximize the capability and automation of the equipment within the cell.

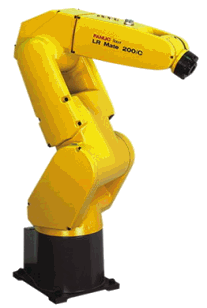

PC and Robot Requirements

Predator RCM requires the Fanuc Robot Server / PCDK Runtime to be purchased from Fanuc Robotics. This PC option needs to be installed on the same PC running Predator RCM. In addition, every Fanuc Robot requires the PC Interface option to be purchased and enabled from Fanuc Robotics.

Predator RCM - Part Numbers

| Part # | Description |

|---|---|

| 20452001 | Predator RCM/1 |

| 20452002 | Predator RCM/2 |

| 20452003 | Predator RCM/3 |

| 20452004 | Predator RCM/4 |

| 20452005 | Predator RCM/5 |

| 20452006 | Predator RCM/6 |

| 20452007 | Predator RCM/7 |

| 20452008 | Predator RCM/8 |

| 20452009 | Predator RCM/9 |

| 20452010 | Predator RCM/10 |

| 20452011 | Predator RCM/11 |

| 20452012 | Predator RCM/12 |

| 204520## | Increments of 1 up to maximum license of /24 |

| 20452910 | Predator RCM Client - Presetter |

Predator RCM Express - Part Numbers

| Part # | Description |

|---|---|

| 20453001 | Predator RCM Express/1 |

| 20453002 | Predator RCM Express/2 |

| 20453003 | Predator RCM Express/3 |

| 20453004 | Predator RCM Express/4 |

| 20453005 | Predator RCM Express/5 |

| 20453006 | Predator RCM Express/6 |

| 20453007 | Predator RCM Express/7 |

| 20453008 | Predator RCM Express/8 |

| 20453009 | Predator RCM Express/9 |

| 20453010 | Predator RCM Express/10 |

| 20453011 | Predator RCM Express/11 |

| 20453012 | Predator RCM Express/12 |

| 204530## | Increments of 1 up to maximum license of /24 |

| 20453910 | Predator RCM Express Client - Presetter |

Predator RCM - Popular Options

| Part # | Description |

|---|---|

| 20459100 | Carousel Storage |

| 20459110 | Conveyer Storage |

| 20459120 | Movable Rack Storage |

| 20459200 | Load/Unload Station (Works while Cell is running) |

| 20459220 | Measuring Module (CMM, Vision or Inspection station) |

| 20459300 | Parts Cleaning Station |

| 20459310 | Part to Tool (Electrodes) |

| 20459330 | Part or Tool RFID (RFID readers and tags not included) |

| 20459340 | Automatic Part Queue |

| 20459400 | Fixture Loading (Fixture Load before Part Load) |

| 20459410 | Parts Handling (Load/Unload of Part Baskets) |

| 20459420 | External Pallet Loader |

| 20459430 | Dynamic Chuck (Load/Unload chucks of different types) |

| 20459500 | External Tool Management |

| 20459510 | Multiple Gripper Optimization |

| 20459900 | Email Notifications |

| 20459910 | Light Tower |

| 20459920 | Fanuc Robot Server RTL-RSR |