Predator MDC™ for Fanuc Robots

Why use Predator MDC with Fanuc Robots?

Leverage the power of Predator MDC with Fanuc Robots to simplify and track robot and CNC machining and productivity:

- Track cycle time, setup time, teardown time, downtimes, idle time, good parts, scrap parts, etc.

- Actual metrics per job, part, operation, traveler, customer, department, shift, user, cell and more

- Works with a wide range of Fanuc Robots

- Ethernet based interface

- Software based no special data collection hardware required

Fanuc Robot Support

Fanuc Robot support is included with the purchase of Predator MDC.

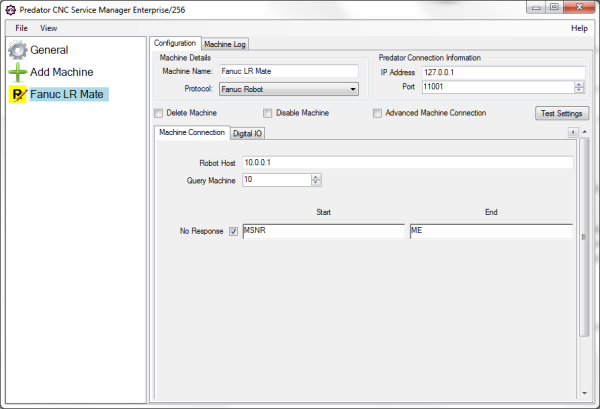

Predator CNC Service

Leverage the power of Fanuc Robot with Predator CNC Service to provide intelligent software based machine monitoring via an Ethernet interface. Predator CNC Service supports robot operation, status, modes, alarms and digital I/Os for all makes and models of Fanuc Robots.

The following software based data collection details are supported:

- Cycle Time

- Idle Time

- Feed Hold

- Teach Pendant Mode

- Emergency Stop

- Robot Alarms

- Digital Inputs & Outputs (6 Styles)

- and more...

Predator MDC supports custom data collection should additional details be required.

NOTE: Predator MDC supports Fanuc Robots via an Ethernet interface.