Predator Integrations™

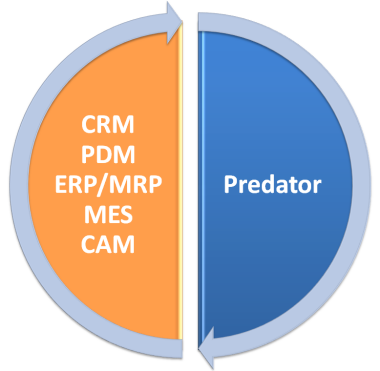

Integrations between Predator and ERP, MRP, MES, CAD, CAM and other 3rd party applications facilitate data sharing and eliminates redundant typing and incorrect data. Typically jobs, parts, operations, personnel, departments, customers, vendors and other details are shared.

There are thousands of different ERP, MES, PLM and other business systems sold worldwide. Each one has different integration options. Over the years, Predator Software has developed a number of integration methods which can be used. Refer to the following examples:

JobBoss and Predator DNC or Predator DNC Enterprise Integration

JobBoss and Predator DNC or Predator DNC Enterprise have been integrated to trigger program transfer via scanning a JobBoss traveler/router. A Predator BCR or PC running Predator PDM or Touch HMI is mounted at each CNC, CMM or test stand to trigger the transaction. JobBoss travelers contain a barcode for each operation. Within this integration, support for JobBoss job numbers, part numbers and operation numbers can be used to validate or establish folder names, filenames and/or extensions for CNC programs, CMM programs and test stand programs and/or test results. Support for Send to CNC, Receive from CNC and dripfeed operation is included.

JobBoss and Predator MDC or Predator MDC Enterprise Integration

JobBoss and Predator MDC or Predator MDC Enterprise have been integrated to automate real-time machine monitoring and manufacturing data collection via scanning a JobBoss traveler/router. A Predator BCR or PC running Predator PDM or Touch HMI is mounted at each CNC, CMM or test stand to trigger the transaction. JobBoss travelers contain a barcode for each operation. Within this integration, support for JobBoss job numbers, part numbers and operation numbers are automatically transferred or validated to the Predator MDC or Predator MDC Enterprise database in real-time. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator MDC and Predator MDC Enterprise is included.

JobBoss and Predator PDM or Predator PDM Enterprise Integration

JobBoss and Predator PDM or Predator PDM Enterprise have been integrated to create a paperless manufacturing experience on the shop floor. After shop floor personnel scan a JobBoss traveler/router. Predator PDM automatically launches providing the released version of the correct CNC program(s), setup sheet(s), tool list(s) and other manufacturing documents automatically. Real-time integration is 100% automated.

Within Predator PDM or Predator PDM Enterprise further integration with Predator DNC, MDC, Tracker and Virtual CNC provides real-time machine communications, machine monitoring, manufacturing data collection, 3D machine simulation, 3D CNC verification and integration with tool, gage and fixture management.

Typically, a shop floor PC is mounted at each CNC, CMM, robot or test stand for operation of Predator PDM. Printing of paper-based routers and bar code readers is eliminated with this real-time integration method. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator PDM and Predator PDM Enterprise is included.

NOTE: Support for the Microsoft Access and Microsoft SQL Server versions of JobBoss are supported.

JD Edwards World and Predator PDM Enterprise Integration

JD Edwards World and Predator PDM or Predator PDM Enterprise have been integrated to create a paperless manufacturing experience on the shop floor. As shop floor personnel select jobs or work orders within JD Edwards World, Predator PDM Predator Enterprise automatically launches providing the released version of the correct CNC program(s), setup sheet(s), tool list(s) and other manufacturing documents automatically. Real-time integration is 100% automated.

Within Predator PDM or Predator PDM Enterprise further integration with Predator DNC, MDC, Tracker and Virtual CNC provides real-time machine communications, machine monitoring, manufacturing data collection, 3D machine simulation, 3D CNC verification and integration with tool, gage and fixture management.

Typically, a shop floor PC is mounted at each CNC, CMM, robot or test stand for operation of JD Edwards and Predator PDM. Printing of paper-based routers and bar code readers is eliminated with this real-time integration method. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator PDM and Predator PDM Enterprise is included.

M1 and Predator DNC or Predator DNC Enterprise Integration

M1 and Predator DNC or Predator DNC Enterprise have been integrated to trigger program transfer via scanning a M1 job traveler. A Predator BCR or PC running Predator PDM or Touch HMI is mounted at each CNC, CMM or test stand to trigger the transaction. M1 job travelers contains barcodes for each sequence. Within this integration, support for M1 job numbers, part numbers and sequence numbers can be used to validate or establish folder names, filenames and/or extensions for CNC programs, CMM programs and test stand programs and/or test results. Support for Send to CNC, Receive from CNC and dripfeed operation is included.

M1 and Predator MDC or Predator MDC Enterprise Integration

M1 and Predator MDC or Predator MDC Enterprise have been integrated to automate real-time machine monitoring and manufacturing data collection via scanning a M1 job traveler. A Predator BCR or PC running Predator PDM or Touch HMI is mounted at each CNC, CMM or test stand to trigger the transaction. M1 job travelers contain barcodes for each sequence. Within this integration, support for M1 job numbers, part numbers and sequence numbers are automatically transferred or validated to the Predator MDC or Predator MDC Enterprise database in real-time. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator MDC and Predator MDC Enterprise is included.

M1 and Predator PDM or Predator PDM Enterprise Integration

M1 and Predator PDM or Predator PDM Enterprise have been integrated to create a paperless manufacturing experience on the shop floor. After shop floor personnel scan a M1 job traveler, Predator PDM automatically launches providing the released version of the correct CNC program(s), setup sheet(s), tool list(s) and other manufacturing documents automatically. Real-time integration is 100% automated.

Within Predator PDM or Predator PDM Enterprise further integration with Predator DNC, MDC, Tracker and Virtual CNC provides real-time machine communications, machine monitoring, manufacturing data collection, 3D machine simulation, 3D CNC verification and integration with tool, gage and fixture management.

Typically, a shop floor PC is mounted at each CNC, CMM, robot or test stand for operation of Predator PDM. Printing of paper-based routers and bar code readers is eliminated with this real-time integration method. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator PDM and Predator PDM Enterprise is included.

NOTE: Support for the Microsoft SQL Server versions of M1 are supported.

Paper-Less and Predator DNC or Predator DNC Enterprise Integration

Paper-Less and Predator DNC or Predator DNC Enterprise have been integrated to trigger program transfer via scanning a Paper-Less traveler. A Predator BCR or PC running Predator PDM or Touch HMI is mounted at each CNC, CMM or test stand to trigger the transaction. Paper-Less travelers contains barcodes for each sequence. Within this integration, support for Paper-Less job numbers, part numbers and sequence numbers can be used to validate or establish folder names, filenames and/or extensions for CNC programs, CMM programs and test stand programs and/or test results. Support for Send to CNC, Receive from CNC and dripfeed operation is included.

Paper-Less and Predator MDC or Predator MDC Enterprise Integration

Paper-Less and Predator MDC or Predator MDC Enterprise have been integrated to automate real-time machine monitoring and manufacturing data collection via scanning a Paper-Less traveler. A Predator BCR or PC running Predator PDM or Touch HMI is mounted at each CNC, CMM or test stand to trigger the transaction. Paper-Less travelers contain barcodes for each sequence. Within this integration, support for Paper-Less job numbers, part numbers and sequence numbers are automatically transferred or validated to the Predator MDC or Predator MDC Enterprise database in real-time. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator MDC and Predator MDC Enterprise is included.

Paper-Less and Predator PDM or Predator PDM Enterprise Integration

Paper-Less and Predator PDM or Predator PDM Enterprise have been integrated to create a paperless manufacturing experience on the shop floor. After shop floor personnel scan a Paper-Less traveler, Predator PDM automatically launches providing the released version of the correct CNC program(s), setup sheet(s), tool list(s) and other manufacturing documents automatically. Real-time integration is 100% automated.

Within Predator PDM or Predator PDM Enterprise further integration with Predator DNC, MDC, Tracker and Virtual CNC provides real-time machine communications, machine monitoring, manufacturing data collection, 3D machine simulation, 3D CNC verification and integration with tool, gage and fixture management.

Typically, a shop floor PC is mounted at each CNC, CMM, robot or test stand for operation of Predator PDM. Printing of paper-based routers and bar code readers is eliminated with this real-time integration method. Support for the Microsoft Access, Microsoft SQL Server or Oracle versions of Predator PDM and Predator PDM Enterprise is included.

NOTE: Support for the Microsoft SQL Server versions of M1 are supported.