Predator PDM™ Software

Over 40% of organizations report struggling with document version control, a critical aspect of document management. This challenge is particularly prevalent in manufacturing sectors, where maintaining accurate and up-to-date documentation is essential for compliance, quality assurance, and operational efficiency.

What is Predator PDM?

Predator PDM is a powerful paperless manufacturing solution designed to streamline and control all aspects of production data. This paperless Production Data Management (PDM) software is ideal for organizing and managing CNC programs, robot programs, CMM programs, PLC programs, setup sheets, safety procedures, quality documents, and other critical production data with full revision control.

Designed to enhance shop floor efficiency, Predator PDM supports seamless integration with other Predator solutions, including Predator DNC, CNC Editor, Virtual CNC, MDC, and Tracker. This comprehensive integration empowers manufacturers to achieve a fully paperless operation, eliminating manual processes and ensuring real-time access to critical production information.

Whether you're managing CNC programs, work instructions, safety protocols, or quality control documents, Predator PDM offers the tools you need to ensure smooth operations, improve traceability, and enhance productivity on the shop floor. Available in two editions to meet your specific needs:

- Predator PDM™

- Predator PDM Enterprise™

Predator PDM provides the right balance of flexibility, control and accountability to simplify adhering to regulatory and international standards including CMMC, CFR21 Part 11 or AS9100. Quality personnel will appreciate that Predator PDM helps to ensure that quality priorities are met by providing documented and structured change management to help avoid DOD, FDA and FAA audit findings. Manufacturing Engineering and CNC programming personnel will appreciate the day-to-day benefits of visualizing the manufacturing process, revision control of manufacturing files and the ability to assign manufacturing and quality statuses. IT personnel will appreciate Predator PDM's use of off the shelf and industry standard technology while reducing operational costs.

Why use Predator PDM?

- Manufacturing driven production document management

- CMMC, ITAR, NIST 800-171, DFARS, 32 CFR Part 2002 and 21 CFR-21 Part 11 Compliance

- Best practice workflow

- Easy Revision Control

- Manufacturing and Quality Statuses

- Manufacturing and Quality Requirements

- Multiple Secure Vaults

- Secure File Viewing for Over 40 File Formats

- Unlimited number of documents

- Users, groups and 140 permissions

- Open API and database architecture

- Windows application integration with ERP, MES or PLM

- Secure Browser / web application integration with ERP, MES or PLM

- Paperless shop floor clients

- Integrates with Predator DNC

- Integrates with Predator Virtual CNC

- Integrates with Predator CNC Editor

- Integrates with Predator MDC

- Integrates with Predator Tracker

- Use your existing ERP and MES bar coded paperwork

- 11 International Languages

- 300+ Online help topics

- Optional Predator PDM Export Service™

- Flexible Licensing and Purchasing

- Made in the USA - Learn more

CMMC, ITAR, NIST 800, DFARS, 32 CFR Part 2002 and 21 CFR Part 11 Compliance

Predator PDM delivers a paperless manufacturing solution that simplifies the management of critical production documents while ensuring compliance with stringent industry regulations. This production document management system helps businesses meet or exceed compliance requirements for ITAR, CMMC, NIST 800-171, DFARS, 32 CFR Part 2002, and 21 CFR Part 11, making it ideal for organizations working with the DOD, FAA, FDA and FDA.

Designed for easy implementation, Predator PDM empowers key manufacturing personnel, including CNC programmers, manufacturing engineers, quality engineers, and shop floor operators, to streamline their operations and maintain full regulatory compliance. The software ensures comprehensive as-built records and detailed history reporting, making it easier to manage audits and simplify documentation tracking.

With configurable manufacturing and quality control requirements, Predator PDM helps address Corrective and Preventive Actions (CAPAs) by enabling immediate corrective actions to resolve issues quickly, as well as implementing preventive measures to avoid recurrence of similar problems in the future.

By integrating compliance and quality management capabilities into your production processes, Predator PDM delivers a streamlined, compliant, and paperless solution for manufacturers in highly regulated industries.

Best practice workflow

Predator PDM features best-practice workflow wizards for releasing, unreleasing, revising, rolling back, checking in, and checking out. Each wizard respects user and group permissions and maintains an ISO 9000-style audit trail.

Easy Revision and Change Control

Revision control is highly automated through intuitive wizards and supports multiple manufacturing and quality statuses for each revision. Engineering change notices and numbers are fully integrated into the revision control workflow. Traditional paper-based change processes can be replaced with streamlined digital equivalents using Predator PDM Enterprise.

Manufacturing and Quality Statuses

Each vault item can be assigned detailed manufacturing and quality statuses—such as Unassigned, Proveout, Run at Risk, Approved, Obsolete, Pending, Submitted 1st Piece, Not Applicable, and various hold reasons. These customizable statuses reflect the current state of each revision and can be tailored to meet specific customer requirements. Statuses can be configured to trigger defined consequences, influencing how revisions are accessed, viewed, and used on the shop floor. Predator PDM supports an unlimited number of user-defined manufacturing and quality statuses.

Manufacturing and Quality Requirements

Major components such as part families, part numbers, machines, etc. can be assigned manufacturing and quality requirements within Predator PDM Enterprise. Requirements can even be assigned to specific revisions. These requirements can be used to establish additional signoffs for special processes or alternate workflows. Requirements can also utilize custom fields to capture as built records to satisfy a CAPA and enforce manufacturing or quality process changes. Within Predator PDM Enterprise requirements can provide a complete audit trail without incurring a huge burden on engineering or shop floor personnel. These customer specific manufacturing and quality requirements can be used to validate the current state of each revision. Requirements can be configured to have consequences and affect how the revision is viewed, used and its availability on the shop floor. Predator PDM supports an unlimited number of customer specific manufacturing and quality requirements.

Multiple Secure Vaults

Create separate vaults for ITAR, CUI, unclassified and as many document classifications as required. Optionally classify individual vault items as required vs. dedicated vaults.

Secure File Viewing for Over 40 File Formats

This all-new application provides file viewing for 40+ file formats within Predator PDM v12. Refer to the following file formats:

- Adobe™ Portable Document Format viewing for .PDF files

- CAD drawing and 3D Print viewing for .PLT, .DXF, .DWG*, .HPGL, .IGES*, .STL, .OBJ and 3MF files

- Document viewing for .RTF, .TXT, and .ODT files

- Hyper Text Markup Language viewing for .HTML files

- Microsoft Excel™ viewing for .XLS, .XLSX and CSV files

- Microsoft Viso™ viewing for .VDW, .VDX, .VSD, .VSDM, .VSDX, .VSS, .VSSM, .VSSX and .VST files

- Microsoft PowerPoint™ viewing for .PPS, .PPSM, and .PPSX files

- Microsoft Word™ viewing for .DOC and .DOCX files

- Image viewing for .BMP, .DIB, .RLE, .TIFF, .GIF, .JPEG, and .PNG files

- Video viewing and audio playing for .MP3, .MP4, .MOV .WAV and .OGG files

- X-ray viewing for .DCM files including tags with contrast style inspection

NOTE* DWG and IGES file viewing is primarily intended for 2D drawings. Full 3D support of all 3D elements with CAD specific flavors are not supported.

Open API and database architecture

Integrate your ERP and MES system with Predator PDM's open APIs (application programming interface) with 300+ methods all fully documented. Develop ERP and shop floor validation, flow part and job numbers from ERP directly into Predator and numerous other automation projects can be completed with C#, C++, VB.Net, VB6, VB script, Windows Script, Delphi and other compatible programming languages.

Predator PDM is based on an open architecture client/server database standard. Select from Microsoft Access, Microsoft SQL Server, or Oracle.

Windows application integration with ERP, MES or PLM

Predator PDM can integrate with Windows based ERP, MES or PLM systems. Over a dozen different command line options can be used to share specific Predator PDM screens, user credentials and database connections.

Secure Browser / web application integration with ERP, MES or PLM

Predator PDM can integrate with browser based or web application based ERP, MES or PLM systems. Over a dozen different command line options can be used to share specific Predator PDM screens, user credentials and database connections. The browser or web application based ERP, MES or PLM systems can be hosted on premise or in the cloud.

Paperless shop floor clients

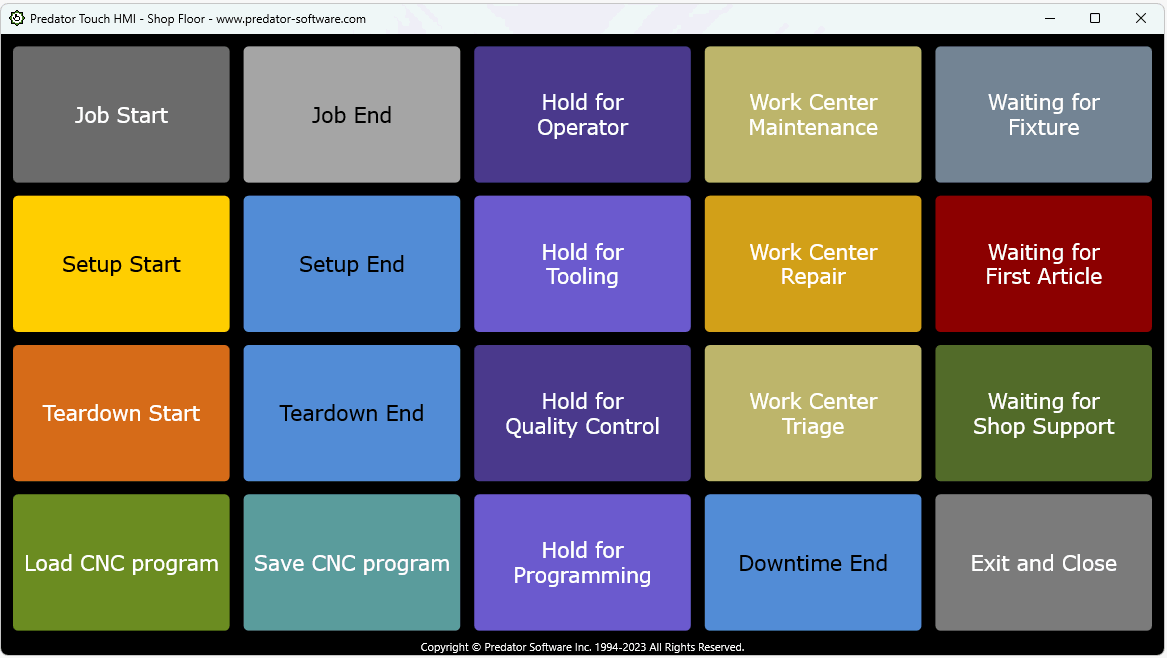

Predator PDM includes a paperless touch screen friendly shop floor client that is fully configurable. It supports using bar codes, QR codes, RFID codes or launch directly from a work schedule. Part change overs are simplified with a fully integrated paperless environment of released and approved revisions. Machinists and shop floor personnel can easily validate the work order or job change over with a grid of details. Notifications of new revisions, manufacturing status or quality status changes reduce scrap and production issues in real-time. Empower machinists and shop floor personnel with functions for send and receive communications, 3D backplotting, downtime reporting, scrap reporting, etc. Several integration examples are listed below:

Integrated Predator DNC Touch client

Machinists using Predator PDM can download released CNC programs to their CNC machines or save edited CNC programs for review by CNC programmers using Predator DNC with a single click. Learn more

Integrated 3D backplotting and verification with Predator Virtual CNC

CNC programmers using Predator PDM can backplot and verify CNC programs in 3D using Predator Virtual CNC with a single click. Learn more

Integrated compare and revise CNC programs with Predator CNC Editor

CNC programmers using Predator PDM can revise and compare their CNC program revisions or uploaded edited CNC programs with the Predator CNC Editor with a single click. Learn more

Integrated machine monitoring and data collection with Predator MDC

Machinists and other shop floor personnel using Predator PDM Enterprise can initiate manual data collection events such as job start, part start, operation start, setup start, etc. in real-time a single click. Learn more

Integrated tool, gage and fixture check outs and check ins with Predator Tracker

Machinists and other shop floor personnel using Predator PDM Enterprise can check tools, gages and fixtures out and back in in real-time with a single click. Learn more

Predator PDM Export Service™

Predator PDM Export Service is a Windows service bundled with professional services by Predator field service engineers for exporting Predator PDM data in real-time. Example tags include job number, work order, lot number, part number, part name, machine number, machine name and vault item details. Real-time data is available to one or more ERP, MES or business applications that support JSON or XML.

- 24x7x365 operation via Windows Service

- Supports an unlimited number of machines

- Supports 25-40 real-time tags per machine

- Supports JSON and XML application integration

- Requires Predator PDM or Predator PDM Enterprise

- Includes onsite implementation and integration consulting

Customers can contact Predator Software at sales@predator-software.com for details and pricing.

Flexible Licensing and Purchasing

Predator PDM software offers flexible licensing options, including per-PC licenses and floating network licenses, available through a one-time purchase or an annual subscription. Pricing for Predator PDM Administrator for Microsoft SQL Server starts at $5,750 for a perpetual license or $2,500 per year with Premier Support included in the subscription. Enhance your revision control and production data management solution with enterprise editions, Predator hardware, PDM client licenses, as well as implementation services, training, and professional consulting—all available for purchase.

For a custom Predator PDM solution, including system architecture, implementation planning, PDM client licensing, multi-seat discounts, Oracle database support, RFID integration, barcoding solutions, and more—contact our sales team at sales@predator-software.com. Get a comprehensive quote and detailed statement of work designed to fit your manufacturing environment.

Predator PDM Enterprise - Part Numbers

| Part # | Descriptions for Microsoft SQL Server licenses |

|---|---|

| 20761000 | Predator PDM Enterprise Administrator for SQL Server |

| 20761010 | Predator PDM Enterprise Client for SQL Server |

| Part # | Descriptions for Oracle licenses |

| 20781000 | Predator PDM Enterprise Administrator for Oracle |

| 20781010 | Predator PDM Enterprise Client for Oracle |

| Part # | Descriptions for Access licenses |

| 20771000 | Predator PDM Enterprise Administrator for Access |

| 20771010 | Predator PDM Enterprise Client for Access |

Predator PDM - Part Numbers

| Part # | Descriptions for Microsoft SQL Server licenses |

|---|---|

| 20762000 | Predator PDM Administrator for SQL Server |

| 20762010 | Predator PDM Client for SQL Server |

| Part # | Descriptions for Oracle licenses |

| 20782000 | Predator PDM Administrator for Oracle |

| 20782010 | Predator PDM Client for Oracle |

| Part # | Descriptions for Access licenses |

| 20772000 | Predator PDM Administrator for Access |

| 20772010 | Predator PDM Client for Access |

NOTE: Predator PDM licenses do not include licenses for Microsoft SQL Server, Oracle or Microsoft Access.

Predator PDM - Popular Options

| Part # | Description |

|---|---|

| 20209010 | Predator Secure HID |

| 20209020 | Predator Touch HMI - Learn more |

| 20209090 | Predator PRemote |

| 20789030 | Predator PDM Export Service - Site License |

| 29900000 | Predator Floating License Manager - Learn more |

Expand with Predator DNC

Every Predator PDM implementation can be expanded to include Predator DNC or Predator DNC Enterprise when machine communications and networking are needed.